Additive Manufacturing

Learn about the different kinds of additive manufacturing #

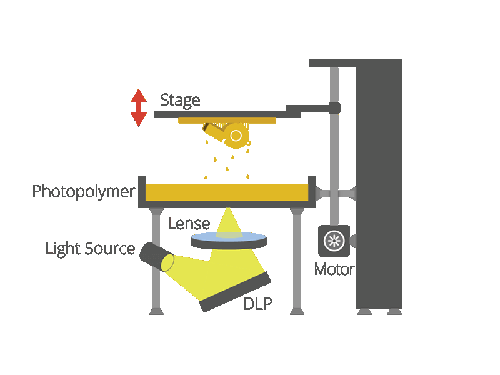

Digital Light Processing (DLP) #

Digital Light Processing is another 3D Printing process very similar to stereolithography.

DLP technology was created in 1987 by Larry Hornbeck of Texas Instruments. It uses digital micro mirrors laid out on a semiconductor chip. This technology is applicable for movie projectors, cell phones and 3D printing.

Like SLA, DLP also works with photopolymers however it works with a different source of light. For DLP, 3D amateurs generally use more conventional sources of lights such as arc lamps.

The material used for printing is liquid plastic resin that is placed in the transparent resin container. The resin hardens quickly when affected by a large amount of light. Printing speed is pretty impressive. The layer of hardened material can be created in a few seconds.

The results of such printing are robust and have an excellent resolution. The biggest advantage of DLP over SLA is that it requires much less materials to be used for detail production, that results in lower cost and it creates less waste.

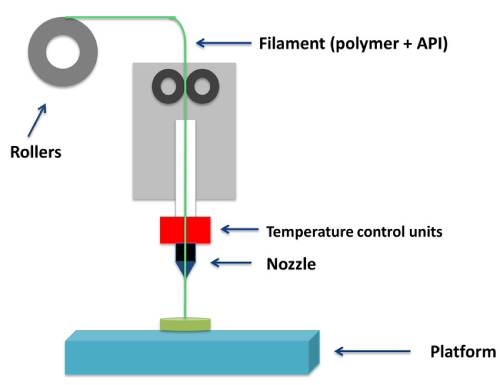

Fused Deposition Modeling (FDM) #

Fused deposition modeling (FDM) technology was developed and implemented by Scott Crump, founder, of Stratasys Ltd in 1980s.

With FDM you can print not only functional prototypes, but also concept models and final end-use products. A positive aspect of this technology is that all parts printed with FDM can go in high-performance and engineering-grade thermoplastic, which is very beneficial for mechanic engineers and manufactures. FDM is the only 3D printing technology that builds parts with production-grade thermoplastics, so things printed are of excellent mechanical, thermal and chemical qualities.

3D printing machines that use FDM Technology build objects layer by layer from the very bottom to the top by heating and extruding thermoplastic filament. When the thin layer of plastic binds to the layer beneath it, it cools down and hardens. Once the layer is finished, the base is lowered to start building of the next layer. Printing time depends on size and complexity of an object printed.Then objects can also be milled, painted or plated afterwards.

FDM technology is widely spread nowadays in variety of industries such as automobile companies like Hyundai and BMW or food companies like Nestle. It is used for new product development, model concept and prototyping and even in manufacturing development. This technology is considered to be simple-to-use and environment-friendly.

Different kind of thermoplastic can be used to print parts. The most common of those are ABS (acrylonitrile butadiene styrene) and PC (polycarbonate) filaments. There are also several types of support materials including water-soluble wax or PPSF (polyphenylsulfone).

Pieces printed using this technology have very good quality of heat and mechanical resistance that allows to use printed pieces for testing of prototypes.

The price for those 3D printers depends on size and model. Professional ones usually cost from $10,000 and more. 3D Printers designed for home use are not so expensive.

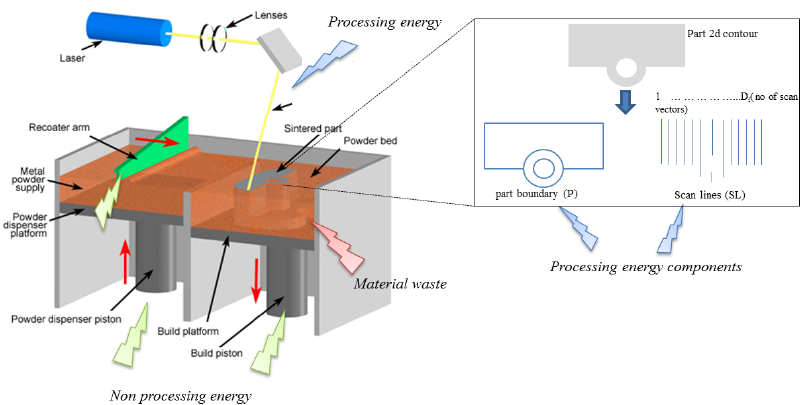

Selective Laser Sintering (SLS) #

Selective Laser Sintering (SLS) is a technique that uses laser as a power source to form solid 3D objects. Carl Deckard, a student of Texas University, and his professor Joe Beaman developed this technique in the 1980s. Stereolithography is in some way very similar to Selective Laser Sintering. The main difference between SLS and SLA is that it uses powdered material in the vat instead of liquid resin as stereolithography does.

Like all other methods listed above the process starts with creation of computer-aided design (CAD) file, which then needs to be converted to .stl format by special software. The material to print with might be anything from nylon, ceramics and glass to some metals like aluminum, steel or silver. Due to the wide variety of materials that can be used with this type of 3d printer the technology is very popular for 3D printing customized products.

SLS is more used among manufactures than 3D amateurs at home as this technology requires the use of high-powered lasers, which makes the printer to be very expensive. Though there are several start-ups the work on development of low-cost SLS printing machines.

Selective Laser Melting (SLM) #

Selective laser melting (SLM) is a technique that also uses 3D CAD data as a source and forms 3D objects by means of a high-power laser beam that fuses and melts metallic powders together.

SLM process fully melts the metal material into solid 3D-dimentional part unlike selective laser sintering. Similarly to other 3d printing methods a CAD file needs to be processed by special software to slice the CAD file information into 2D layers. The file format used by printing machine is also a standard .stl file. Once the file is loaded the printing machine’s software assigns parameters and values for construction of the path.

The fine metal powder is evenly distributed onto a plate, then each slice of 2D layer image is intensively fused by applying high laser energy that is directed to the powdered plate. The energy of laser is so intense that metal powder melts fully and forms a solid object. After the layer is completed the process starts over again for the next layer. Metals that can be used for SLM include stainless steel, titanium, cobalt chrome and aluminum.

This method of printing is widely applied to parts with complex geometries and structures with thin walls and hidden voids or channels. Lots of pioneering SLM projects were dedicated to aerospace application for different lightweight parts. SLM is not widely spread among at-home users but mostly among manufactures of aerospace and medical orthopedics.

#

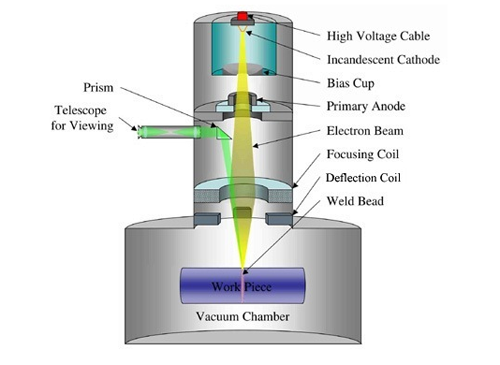

EBM is a powder bed fusion technique. While SLM uses high-power laser beam as its power source, EBM uses an electron beam instead, which is the main difference between these two methods.

The material used in EBM is metal powder that melts and forms a 3D part layer by layer by means of a computer, that controls the electron beam in high vacuum. Contrary to SLS, EBM goes for full melting of the metal powder. The process is usually conducted under high temperatures up to 1000 °C.

The process of EBM is rather slow and expensive, and the availability of materials is limited, making the method not so popular though it is still used in some of manufacturing processes. The application of EBM is mainly focused on medical implants and aerospace area.

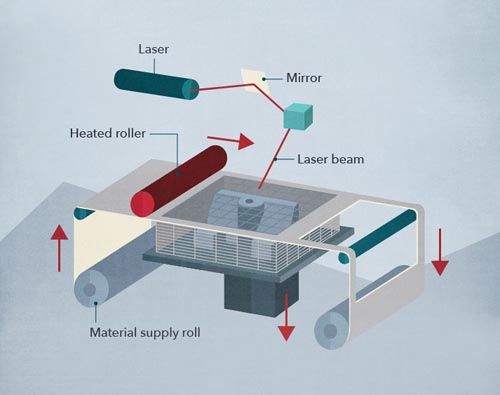

Laminated Object Manufacturing (LOM) #

Laminated object manufacturing (LOM) is a rapid prototyping system that was developed by the California-based company Helisys Inc.

Layers of adhesive-coated paper, plastic or metal laminates are fused together using heat and pressure and then cut to shape with a computer controlled laser or knife. Post-processing of 3D printed parts includes such steps as machining and drilling.

LOM is one of the most affordable and fastest 3D printing methods. The cost of printing is low due to un-expensive raw materials. Objects printed with LOM can be relatively big, that means that no chemical reaction is needed to print large parts.

Currently, Cubic Technologies, the successor to Helisys Inc., is the main manufacturer of LOM printers. There are not too many companies these days that work with LOM technology. But it’s worth mentioning the Irish company Mcor Technologies Ltd. that sells LOM 3D printers. Their devices are widely being used by artists, architects and product developers to create affordable projects from usual letter paper.

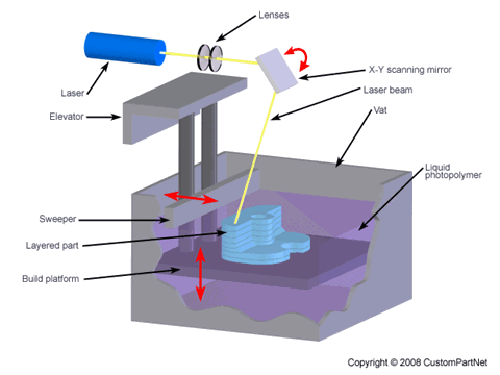

Stereolithography #

Stereolithography is an additive manufacturing process that works by focusing an ultraviolet (UV) laser on to a vat of photopolymer resin. With the help of computer aided manufacturing or computer-aided design (CAM/CAD) software, the UV laser is used to draw a pre-programmed design or shape on to the surface of the photopolymer vat. Photopolymers are sensitive to ultraviolet light, so the resin is photochemically solidified and forms a single layer of the desired 3D object. Then, the build platform lowers one layer and a blade recoats the top of the tank with resin. This process is repeated for each layer of the design until the 3D object is complete. Completed parts must be washed with a solvent to clean wet resin off their surfaces. It is also possible to print objects “bottom up” by using a vat with a transparent bottom and focusing the UV or deep-blue polymerization laser upward through the bottom of the vat. An inverted stereolithography machine starts a print by lowering the build platform to touch the bottom of the resin-filled vat, then moving upward the height of one layer. The UV laser then writes the bottom-most layer of the desired part through the transparent vat bottom. Then the vat is “rocked”, flexing and peeling the bottom of the vat away from the hardened photopolymer; the hardened material detaches from the bottom of the vat and stays attached to the rising build platform, and new liquid photopolymer flows in from the edges of the partially built part. The UV laser then writes the second-from-bottom layer and repeats the process. An advantage of this bottom-up mode is that the build volume can be much bigger than the vat itself, and only enough photopolymer is needed to keep the bottom of the build vat continuously full of photopolymer.

This approach is typical of desktop SLA printers, while the right-side-up approach is more common in industrial systems. Stereolithography requires the use of supporting structures which attach to the elevator platform to prevent deflection due to gravity, resist lateral pressure from the resin-filled blade, or retain newly created sections during the “vat rocking” of bottom up printing. Supports are typically created automatically during the preparation of CAD models and can also be made manually. In either situation, the supports must be removed manually after printing.

Stereolithography is often used for prototyping parts. For a relatively low price, Stereolithography can produce accurate prototypes, even of irregular shapes. Businesses can use those prototypes to assess the design of their product or as publicity for the final product.